Strategic solutions for products, packaging and visual identity.

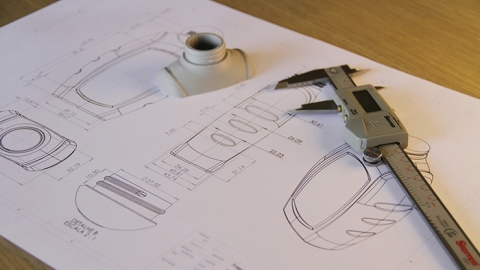

3D printing in our projects

We use this tool to increase the quality and provide more agility to the projects. It allows us tangible ideas that hitherto were only on paper and on the computer. This process eliminates errors and allows our clients to approve the design of a new product with a lot more confidence.Another important aspect is that the equipment is within the Studio Olea, which enables us to ensure confidentiality to the companies of what is being developed.

Characteristics

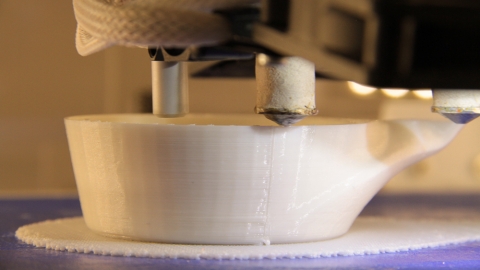

Technology

(FDM) Fused Deposition Modeling. It works with the deposition of layers of thermoplastic materials one upon another to form the desired part.

Useful printing area

10.4 X 10.0 X 9.0 in (265 X 255 X 230 mm).

NOTE: In case of larger pieces, we print in parts and we glue to arrive at the finished product.

Definition of the printing layer

0.004in (0.1mm) per layer

Materials used

PLA - It is a rigid plastic with low environmental impact because it is derived from renewable sources based on starch. It is recommended for the printing of large parts because it is more stable.

ABS - It is a plastic known for its strength and industrial properties, more resistant to high temperatures.

Colors

For both materials, we use white, which is the default color. Other colors on request.

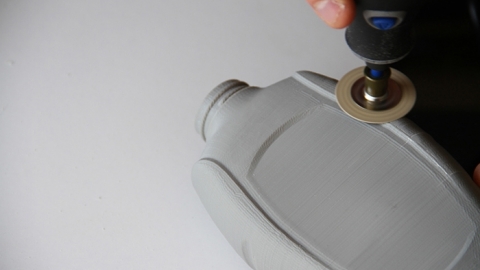

Finishing

Preencha o formulário abaixo e entraremos em contato